Failure Analysis

Failure evaluation requires specialized knowledge and technical methods to characterize material and component properties.

The objective of each failure analysis is to determine the damage mechanism, and to define measures that will prevent future failures.

There are many possible parameters that can cause the failure of components and systems.The modification of these parameters and implementation of specific measures are often successful in preventing further failures.

Such measures may include:

- Implementing design modifications

- Selecting alternative materials

- Applying coatings or an overlayer

- Optimizing manufacturing procedures

In some cases, damage may be avoided by adjusting service conditions, such as:

- Reducing the temperature

- Lowering flow rates

- Removing a particularly aggressive component from a corrosive medium

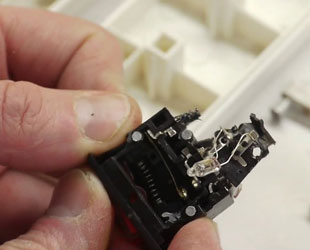

- Gear component exhibiting break-out .jpg, Analysis of a metallographic sample by optical microscopy.

We discuss your case with you and define a detailed analysis program to identify the cause of the failure, factoring in the type of failure and the urgency of the situation. The microstructure and fracture surfaces are frequently analyzed, in addition to visual and/or microscopic inspections. We have in-house equipment for precise chemical, physical, and mechanical measurements. We are able to work with even the tiniest samples of corrosion products, residues, or other contaminants. Larger parts can be tested non-destructively on-site using surface replication techniques and ultrasonic crack detection.